We purchased a lithium-ion battery in 2019 and installed it on one of our feeder lines. The purchase was part of a project we did in partnership with the Ministry of Energy Smart Grid Fund and Panasonic Canada. The Smart Grid Fund financed around 20% of the project while Panasonic Canada provided the battery at cost.

The battery itself was 250 kW / 250 kWh. This means it can provide power at up to 250 kW at any point in time but only holds 250 kWh. Compared to a Tesla Powerwall which is 10 kW / 13.5 kWh this is large but compared to most industrial and utility-sized batteries this is small.

The project had two primary objectives:

- To see if the battery could be used to increase the capacity of a feeder line to support distributed generation; and

- To see if the battery could be used economically to reduce the peak demand on the NOTL Hydro system.

Feeder Line Capacity

There are limits to how much generation can be placed on a feeder line based on the load of that line. There is an engineering standard (IEEE 1547) that recommends the amount of generation be restricted to one third of the minimum load on that line. The limits are due to the need to manage short circuit or fault risk. I am not going to try to explain this risk as it relates to the amount of generation on a line as I am still trying to understand it myself. However, I do see this risk as a real future impediment to the expansion of the use of solar power and other distributed energy generation in Ontario.

It should be noted that IEEE 1547 is a guideline and not physical restriction. Utilities can create their own standards; Hydro One has their own engineering calculation that they use. The risk can also be reduced or eliminated using additional protective equipment such as transfer trips. These are expensive so are not economical on small generation installations but are usually a utility requirement on larger ones.

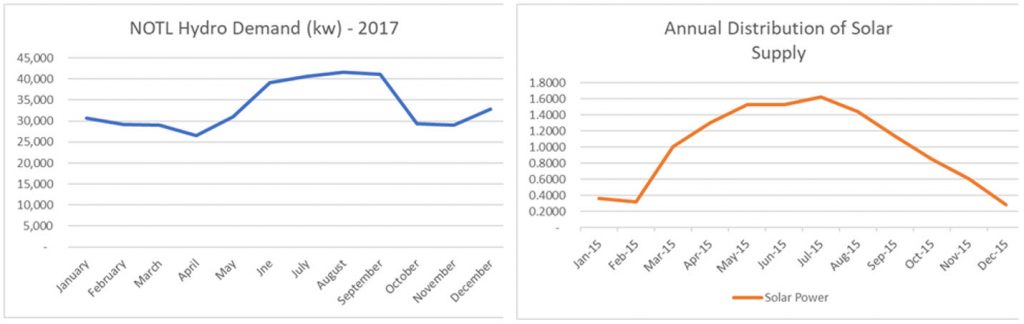

To better understand the challenge, look at the two graphs below. The first shows the demand for power in NOTL in 2017 by month. Demand is highest in the summer (air conditioning) but also high in winter (heating). Anywhere north of NOTL, which is pretty well all of Ontario, will have higher peaks in the winter and slightly lower ones in the summer. In the spring and fall, when we have our windows open for the fresh air, demand is lower. The second graph shows the distribution of solar power generation across the year. Generation is highest in the spring and summer and very low in the winter when we can go weeks without seeing the sun.

The IEEE 1547 standards are not an issue in the summer; there is lots of load on the system to cover the solar generation. No issue in the winter either as there is little solar generation. The challenges are in the spring, especially, and in the fall when demand is low but solar supply is high.

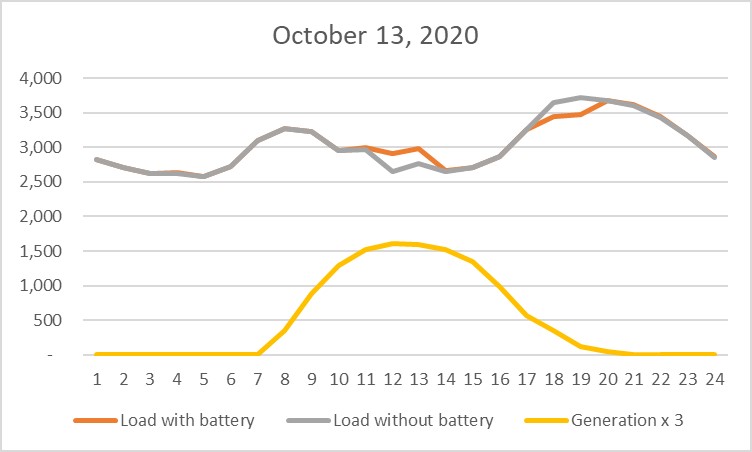

The idea was to use the battery to create additional load or demand at the time of day when the gap between the load on the feeder and the solar generation on the feeder (multiplied by 3) was at its lowest. Through historical analysis we were able to determine that this was usually at around 1:00 PM. We therefore charged the battery at this time and discharged it around 6:00 PM when the demand for electricity is at its highest.

As can be seen in the chart below showing one of the days with the best results, this was successful. On this day, the battery created load at the right time so that the gap between the load and the generation grew. This means that, with a battery, more solar generation could be added to the feeder.

Across the full test period the use of the battery showed a positive result and the use of the battery would support placing more solar generation on the feeder line. However, this just proves that the technology works in this capacity. It does not mean it makes economic sense to do this. Batteries are still much too expensive for that. It may be a strategy for the future.

A side benefit of the project was that it demonstrated that by doing a more detailed analysis it can be made clear that a feeder line can support more distributed generation. Demand on a feeder line is at its lowest at night and then in the early morning. There is no solar generation at night and very little in the early morning. Instead, midday is usually the time when the gap between load and generation is at its lowest so midday demand, which is normally higher than in the morning, can be used for the purpose of determining how much generation can be allowed under IEEE 1547. This would allow a utility to raise how much solar generation can be safely installed on a feeder line.

Peak Shaving

The second objective was to see if the battery could be used to economically reduce the demand on a feeder line at peak times. The peak demand (and highest price) time is usually around 6:00 PM. The idea was to charge the battery in the middle of the night when demand (and the price) is low and then discharge it at the peak times.

Unfortunately, this did not work as charging and discharging in this manner cost money. The technology worked fine, that was never in doubt, and we were able to estimate in advance the best times to charge and discharge but there was no financial benefit. There were four reasons for this:

- A battery has an efficiency level. This is the amount of energy it discharges compared to the amount of energy needed to charge it. This battery was 84% efficient so there is a cost for paying for the 16% of the energy lost in the process.

- The battery needs energy even when it is not charging or discharging. Even though this is only a few kWh per hour this still adds up over time.

- The average hourly price for electricity was very low at the time of the study at a little over 1 cent per kWh. This means even if the price doubles between charging and discharging the difference is only 1 cents. The reason for this is the bulk of the cost of electricity at this time was the global adjustment which was around 11 cents per kWh.

- The global adjustment is applied at the same rate no matter when the power is used. There is no time of use adjustment no matter what the level of demand at the varying times. As the global adjustment was over 90% of the cost of electricity there is no financial benefit for trying to shift demand.

We reran this peak saving experiment in early 2022 as the hourly priced had increased to being over 4 cents per kWh on average while the global adjustment declined correspondingly. The results were better but still not economical with the uniform global adjustment being the most significant challenge.

Conclusion

Overall, this was an interesting experiment. Battery technology is still too expensive to be applied practically on the grid but this project did demonstrate a few of the many uses to which batteries could be applied if, and hopefully when, the costs come down.